K209B LSZH Armoured Optical Fiber Cables

Application

The cables are designed for long distance telecommunication and using optical fibres in urban railways infrastructure. These low smoke halogen-free cables are laid on hooks, pulled through ducts or cable trays.

Standards

- RATP K209B or RATP K209A

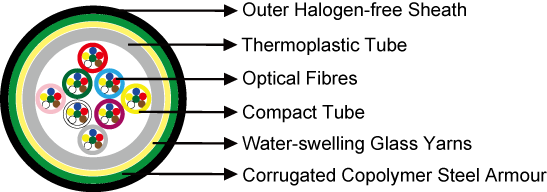

Construction

- Compact Tube: 6 or 12 singlemode optical fibres G652 or multimode fi bers assembled under thermoplastic “peelable” skin. Tube diameter: 1mm.

- Filling: Water-swelling yarns.

- Tube: Thermoplastic.

- Peripheral Strength Member: Water-swelling glass yarns.

- Armour: Corrugated steel tape armour 25/100.

- Sheath: LSZH.

Optional

- K209A Type: For K209A type, the cables have loose tubes with 6-12 fi bers, steel wire strand as central strength member, glass yarn reinforced, incorporating a corrugated steel tape armour and an outer UV stabilized LSZH jacket.

Electrical Characteristics at 20℃

Optical & Geometrical Properties for Single Mode Fibers

| Maximum Attenuation | G652 | |

| @1310nm | dB/km | 0.35 |

| @1550nm | dB/km | 0.22 |

| Maximum Chromatic Dispersion | ||

| Between 1260 and 1360nm | ps/(nm/km) | 3.5 |

| Between 1530 and 1565nm | ps/(nm/km) | 19 |

| Zero Dispersion Wavelength | nm | 1310±11 |

| Zero Dispersion Slope | ps/(nm2.km) | 0.09 |

| Numerical Aperture | 0.14 | |

| Point discontinuity | dB | 0.1 |

| PMD (individual fi ber) | ps/km | 0.2 |

| Maximum Cutoff Wavelength | nm | 1260 |

| Cladding Diameter | um | 125±1 |

| Core/Cladding Concentricity Error | um | ≤0.5 |

| Cladding Non Circularity | % | ≤1 |

| Coating Non Circularity | % | ≤6 |

| Proof Test Level | Kpsi (GN/m2) | 100 (0.7) |

| Crush Resistance | N/cm | 300 |

| Maximum Laying Tension | N | 3000 |

Optical & Geometrical Properties for Multimode Fibers

| 50/125 | 62.5/125 | ||

| Maximum Attenuation | |||

| @850nm | dB/km | ≤2.5 | ≤3.0 |

| @1300nm | dB/km | ≤0.7 | ≤0.8 |

| Maximum Chromatic Dispersion | |||

| @850nm | MHz*km | ≥500 | ≥200 |

| @1300nm | MHz*km | ≥800 | ≥500 |

| Zero Dispersion Wavelength | nm | 1310 | 1310 |

| Numerical Aperture | - | 0.20±0.015 | 0.275±0.015 |

| Core Diameter | um | 50±3 | 62.5±3 |

| Cladding Diameter | um | 125±2 | 125±2 |

| Core/Cladding Concentricity Error(Offset) | um | ≤1.5 | ≤1.5 |

| Coating-Clad Concentricity Error(Offset) | um | ≤8 | ≤8 |

| Core Non-Circularity | % | ≤6 | ≤6 |

| Cladding Non-Circularity | % | ≤2 1 | ≤2 1 |

| Coating Diameter | um | 245±10 | 245±10 |

| Proof-Test Level | Kpsi (GN/m2) | 100 (0.7) | 100 (0.7) |

Mechanical and Thermal Properties

- Bending Radius: 20×OD

- Temperature Range: -40℃ to +60℃ (during operation); -10℃ +60℃ (during installation)

Dimensions and Weight

K209A

| Cable Code | No. of fibres |

Distribution | Nominal Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| RO/K209A-ML-C-9-TnxFn-SR-(STA)H | 1-36 | 6 fi bre per tubes | 1.8 | 12 | 190 |

| RO/K209A-ML-C-9-TnxFn-SR-(STA)H | 42-72 | 6/12 fi bre per tubes | 1.8 | 13.5 | 230 |

Tn: Number of tubes; Fn: Number of fi bers in a tube

K209B

| Cable Code | No. of fibres |

No of Tubes x No of Fibers/Tube |

Nominal Sheath Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| Singlemode Fibres From 6 to 36 OF – G652 | |||||

| RO/K209B-ML-C-9-2x6-F-(STA)H | 12 | 2 tubes of 6 OF | 1.8 | 13 | 112 |

| RO/K209B-ML-C-9-4x6-F-(STA)H | 24 | 4 tubes of 6 OF | 1.8 | 13 | 112 |

| RO/K209B-ML-C-9-6x6-F-(STA)H | 36 | 6 tubes of 6 OF | 1.8 | 13 | 112 |

| Singlemode Fibres From 48 to 72 OF – G652 | |||||

| RO/K209B-ML-C-9-8x6-F-(STA)H | 48 | 8 tubes of 6 OF | 2.5 | 15.5 | 230 |

| RO/K209B-ML-C-9-6x12-F-(STA)H | 72 | 6 tubes of 12 OF | 2.8 | 15.5 | 230 |

| Multimode Fibres From 6 to 36 OF – 50/125 | |||||

| RO/K209B-ML-C-9-1x6-F-(STA)H | 6 | 1 tubes of 6 OF | 1.8 | 13 | 112 |

| RO/K209B-ML-C-9-2x6-F-(STA)H | 12 | 2 tubes of 6 OF | 1.8 | 13 | 112 |