TYPE D1 & D2 Railway Signalling Cable

Application

The cables are designed for railway signalling systems. The cables are suitable for use in d.c. circuits where the nominal voltage to earth does not exceed 1100 volts and are suitable for installation in ducts.

Standards

- NR/PS/SIG/00005(formerly RT/E/PS/00005)

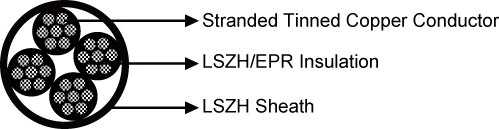

Construction

- Conductors: Tinned stranded copper, according to IEC 60228 class 2& BS 6360.

- Insulation: LSZH or EPR Type GP4 to BS 7655.

- Core Wrapping: Plastic tape(s) with overlapping.

- Sheath: LSZH.

Electrical Characteristics at 20℃

| Nominal Conductor Cross Section | mm² | 0.75 | 1.5 | 2.5 | 10.0 | 16.0 | 35.0 | 70.0 | 95 |

| Maximum Conductor DC Resistance | Ω/km | 24.8 | 12.2 | 7.56 | 1.84 | 1.16 | 0.529 | 0.27 | 0.195 |

| Voltage Rating | KV | 0.65/1.1 | |||||||

| Nominal Insulation Thickness | mm | 0.85 | 0.8 | 0.8 | 1.0 | 1.0 | 1.2 | 1.4 | 1.6 |

Mechanical and Thermal Properties

- Minimum Bending Radius: 6×OD (static); 15×OD (dynamic)

- Temperature Range: -25℃ to +85℃ (during operation); -10℃ to +85℃ (during installation)

Dimensions and Weight

| Cable Code | No. of cores& Nominal Conductor Cross Sectional Area No.×mm² |

No. & Nominal Diameter of Strands No/mm |

Nominal Sheath Thickness mm |

Overall Diameter Min/Max mm |

Nominal Weight kg/km |

| Type D1 | |||||

| RS/D1-3GH-1G0.75 | 1×0.75 | 7/0.37 | 2.0 | 6.5/8.1 | 25 |

| RS/D1-3GH-1G1.5 | 1×1.5 | 7/0.53 | 2.0 | 6.8/8.5 | 30 |

| RS/D1-3GH-1G2.5 | 1×2.5 | 7/0.67 | 2.0 | 7.2/8.9 | 34 |

| RS/D1-3GH-1G10 | 1×10.0 | 7/1.35 | 2.0 | 9.4/11.8 | 205 |

| RS/D1-3GH-1G35 | 1×35.0 | 19/1.53 | 2.0 | 12.9/16.1 | 495 |

| Type D2 | |||||

| RS/D2-3GH-2G1.5 | 2×1.5 | 7/0.53 | 2.0 | 9.4/12.1 | 140 |

| RS/D2-3GH-2G2.5 | 2×2.5 | 7/0.67 | 2.0 | 10.5/13.1 | 170 |

| RS/D2-3GH-2G10 | 2×10.0 | 7/1.35 | 2.0 | 15.0/18.7 | 383 |

| RS/D2-3GH-2G16 | 2×16.0 | 7/1.70 | 2.0 | 16.7/20.9 | 625 |

| RS/D2-3GH-2G35 | 2×35.0 | 19/1.53 | 2.2 | 22.3/27.8 | 994 |

| RS/D2-3GH-2G70 | 2×70.0 | 19/2.14 | 2.4 | 28.8/36.0 | 2121 |

| RS/D2-3GH-2G95 | 2×95.0 | 19/2.52 | 2.6 | 33.2/41.5 | 2760 |

| RS/D2-3GH-4G0.75 | 4×0.75 | 7/0.37 | 2.0 | 10.2/12.8 | 150 |

| RS/D2-3GH-7G0.75 | 7×0.75 | 7/0.37 | 2.0 | 11.8/14.7 | 225 |

| RS/D2-3GH-10G0.75 | 10×0.75 | 7/0.37 | 2.0 | 14.4/18.0 | 280 |

| RS/D2-3GH-12G0.75 | 12×0.75 | 7/0.37 | 2.0 | 14.8/18.5 | 321 |

| RS/D2-3GH-19G0.75 | 19×0.75 | 7/0.37 | 2.0 | 17.0/21.3 | 425 |

| RS/D2-3GH-27G0.75 | 27×0.75 | 7/0.37 | 2.0 | 20.1/25.1 | 606 |

| RS/D2-3GH-37G0.75 | 37×0.75 | 7/0.37 | 2.2 | 22.7/28.4 | 786 |

| RS/D2-3GH-48G0.75 | 48×0.75 | 7/0.37 | 2.2 | 25.7/32.2 | 972 |

| RS/D2-3GH-4G1.5 | 4×1.5 | 7/0.53 | 2.0 | 10.9/13.7 | 250 |

| RS/D2-3GH-7G1.5 | 7×1.5 | 7/0.53 | 2.0 | 12.6/15.8 | 370 |

| RS/D2-3GH-10G1.5 | 10×1.5 | 7/0.53 | 2.0 | 15.6/19.4 | 410 |

| RS/D2-3GH-12G1.5 | 12×1.5 | 7/0.53 | 2.0 | 16.0/20.0 | 410 |

| RS/D2-3GH-19G1.5 | 19×1.5 | 7/0.53 | 2.0 | 18.5/23.1 | 615 |

| RS/D2-3GH-27G1.5 | 27×1.5 | 7/0.53 | 2.2 | 22.2/27.8 | 897 |

| RS/D2-3GH-37G1.5 | 37×1.5 | 7/0.53 | 2.2 | 25.1/31.4 | 1126 |

| RS/D2-3GH-48G1.5 | 48×1.5 | 7/0.53 | 2.4 | 28.1/35.1 | 1280 |

| RS/D2-3GH-4G2.5 | 4×2.5 | 7/0.67 | 2.0 | 11.9/14.8 | 340 |

| RS/D2-3GH-7G2.5 | 7×2.5 | 7/0.67 | 2.0 | 13.8/17.2 | 500 |

| RS/D2-3GH-10G2.5 | 10×2.5 | 7/0.67 | 2.0 | 17.1/21.3 | 680 |

| RS/D2-3GH-12G2.5 | 12×2.5 | 7/0.67 | 2.0 | 17.6/22.0 | 613 |

| RS/D2-3GH-19G2.5 | 19×2.5 | 7/0.67 | 2.0 | 20.4/25.5 | 815 |

| RS/D2-3GH-27G2.5 | 27×2.5 | 7/0.67 | 2.2 | 24.6/30.7 | 1200 |

| RS/D2-3GH-37G2.5 | 37×2.5 | 7/0.67 | 2.4 | 27.8/34.7 | 1600 |

| RS/D2-3GH-48G2.5 | 48×2.5 | 7/0.67 | 2.6 | 31.2/39.0 | 1960 |