FRA 155/S Multicore

Application

Multicore cable very high resistance to temperature designed for internal wiring in lamps, heating appliances and distribution boxes in apparatus, mechanical and plant engineering, etc. Used for fixed and fl exible application in dry, humid and wet rooms.

Standards

- IEC 60332-1, EN 50265-2-1 (flame retardant)

- EN 50266-2 (non-flame propagating)

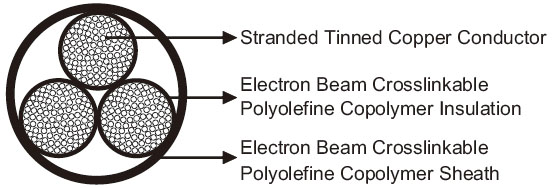

Construction

- Conductors: Class 5 stranded tinned copper to IEC60228/VDE 0295.

- Insulation: Electron beam crosslinkable polyolefine copolymer.

- Sheath: Electron beam crosslinkable polyolefi ne copolymer.

Electrical Characteristics at 20℃

| Nominal Conductor Cross Section | mm² | 0.25 | 0.50 | 0.75 | 1.0 | 1.5 | 2.5 |

| Maximum Conductor Resistance | Ω/km | 85.9 | 40.1 | 26.7 | 20.0 | 13.7 | 8.21 |

| Voltage Rating | V | 450/750V (≤0.5mm²); 600/1000V (>0.5mm²) | |||||

Mechanical and Thermal Properties

- Minimum Bending Radius: 4xOD (Static); 6xOD (Flexing)

- Temperature Range: -55℃ ~+155℃ (Static); -40℃ ~+120℃ (Flexing)

- Short Circuit Temperature: +280℃

Dimensions and Weight

| No. of cores& Nominal Conductor Cross Sectional Area No.×mm² |

Number and Nominal Diameter of Strands No./mm |

Nominal Insulation Thickness mm |

Nominal Overall Diameter mm |

Nominal Weight kg/km |

| 4×0.25 | 19/0.13 | 0.5 | 5.4 | 33 |

| 2×0.5 | 16/0.20 | 0.5 | 5.2 | 30 |

| 3×0.5 | 16/0.20 | 0.5 | 5.6 | 40 |

| 8×0.5 | 16/0.20 | 0.5 | 8.8 | 102 |

| 16×0.5 | 16/0.20 | 0.5 | 10.7 | 166 |

| 3×0.75 | 24/0.20 | 0.6 | 6.7 | 59 |

| 4×0.75 | 24/0.20 | 0.6 | 7.5 | 80 |

| 2×1 | 30/0.20 | 0.6 | 7.0 | 61 |

| 3×1 | 30/0.20 | 0.6 | 7.6 | 77 |

| 2×1.5 | 30/0.25 | 0.6 | 7.5 | 66 |

| 3×1.5 | 30/0.25 | 0.6 | 7.9 | 92 |

| 4×1.5 | 30/0.25 | 0.6 | 8.8 | 117 |

| 5×1.5 | 30/0.25 | 0.6 | 10.1 | 150 |

| 3×2.5 | 50/0.25 | 0.7 | 9.9 | 145 |

| 4×2.5 | 50/0.25 | 0.7 | 11.0 | 186 |

| 5×2.5 | 50/0.25 | 0.7 | 12.0 | 223 |